Contract Filter Manufacturing

Outsource your mid to large-volume custom industrial and OEM filter manufacturing. View Manufacturing CapabilitiesGet a Custom QuoteCustom Filter Design and Manufacturing

Our sales and engineering team is happy to work with you on design, pricing, and application for your custom filter needs.

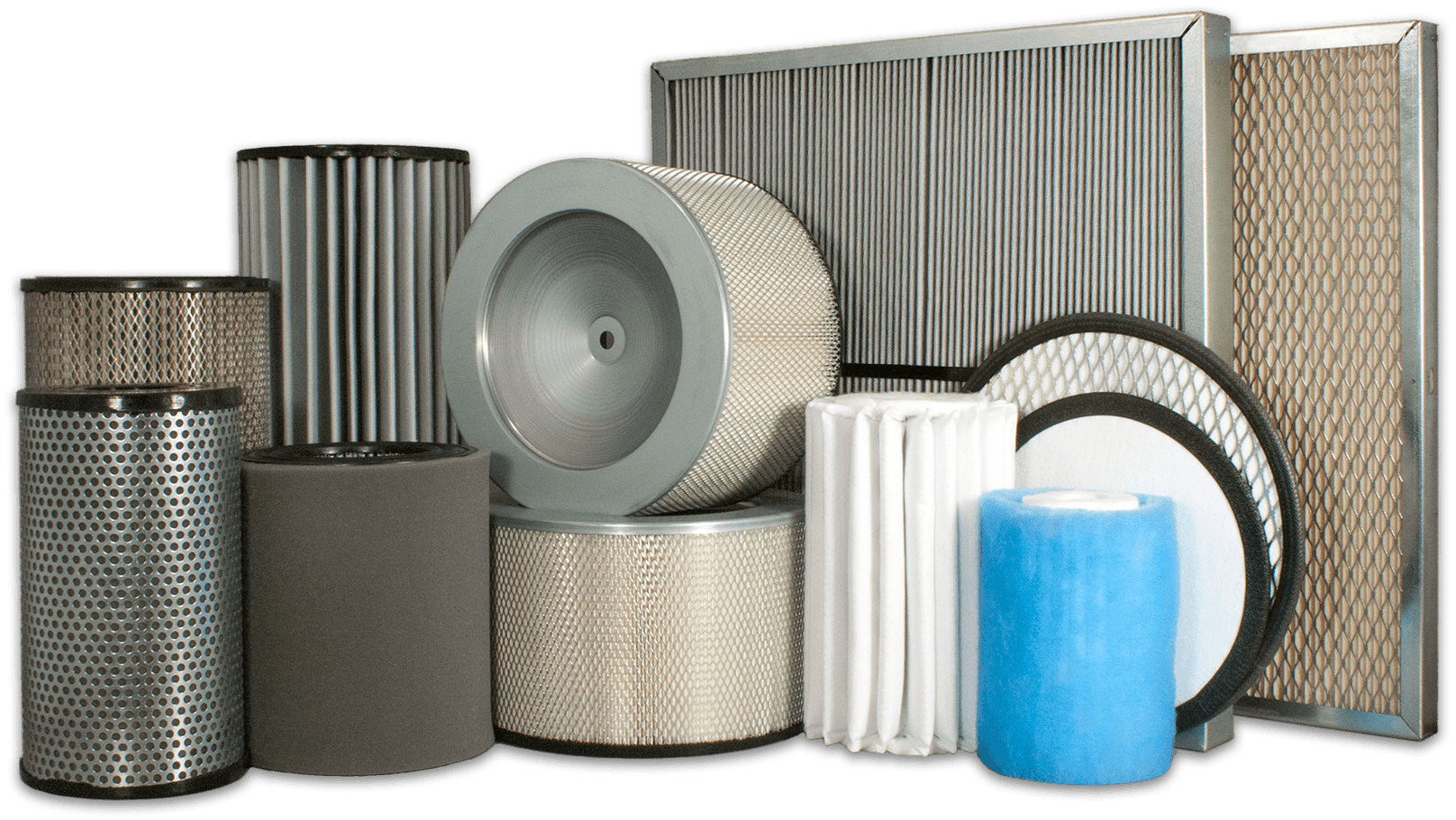

We offer various filter types, media choices, and construction options. We can even work with you to source specialty raw materials for your unique application.

HEPA, ULPA, & ASHRAE Filters for OEMs

With our acquisition of Roome Technologies, we have expanded our custom filter design and manufacturing capabilities with a significant focus on the HEPA filtration industry.

We manufacture HEPA, ULPA, and ASHRAE filters for OEMs of room air purifiers, non-critical medical and dental equipment, aircraft cabin filtration, and more!

We are also able to provide contract pleating for other filter manufacturers.

High Volume Quantities

Orders of 200 or more pieces are considered high-volume and allow our purchasing team to secure raw materials at locked-in pricing for the benefit of our contract holders.

OEM Filter Manufacturing Capabilities

Sidco has a variety of capabilities to manufacture for OEMs. Our team is also happy to evaluate new designs, specifications, or large-volume filter manufacturing projects.

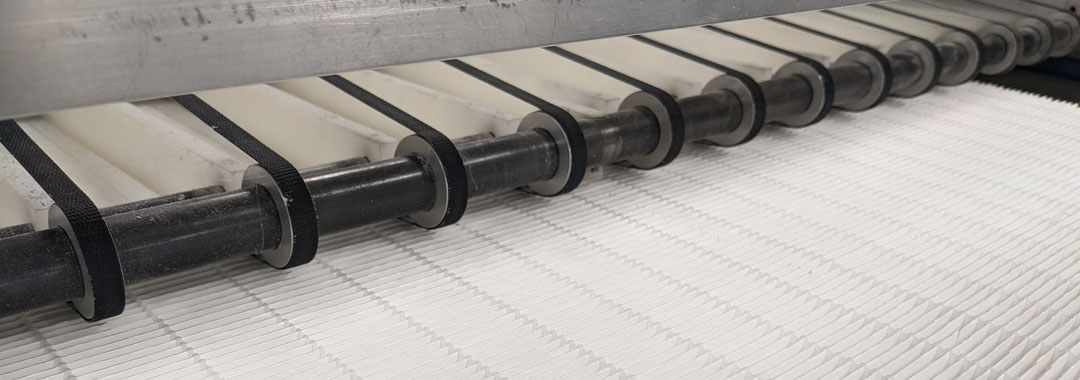

Pleating Capabilities

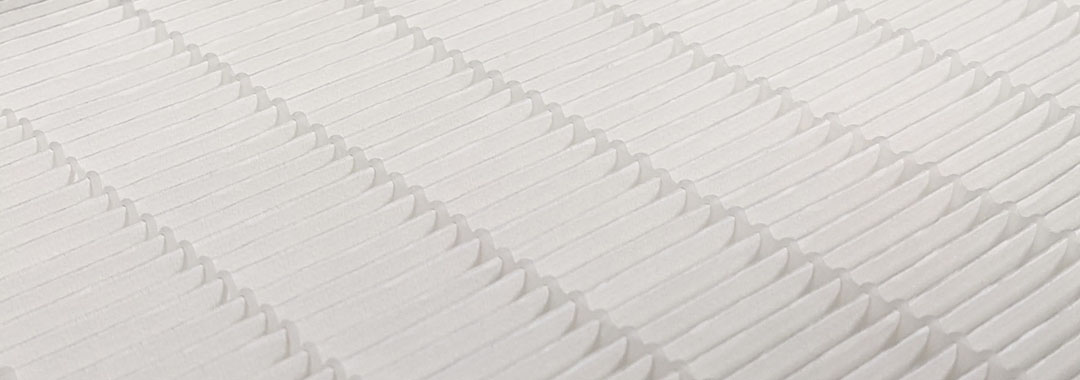

We use top-of-the-line pleating technology. Pleat depths range from 0.25″ to 6.0″ on most filter media. Contract pleating for OEMs is also available!

Much of our filter media can be layered, pleated, and adjusted to maximize surface area to optimize performance and efficiency ratings.

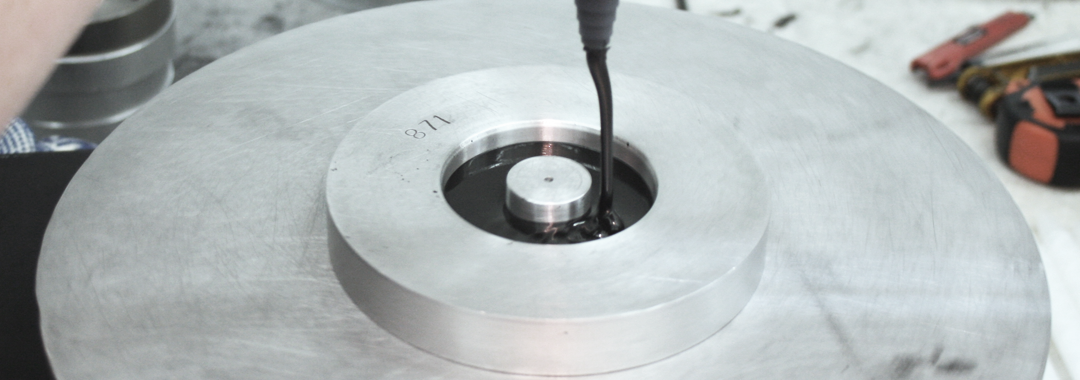

Molding Capabilities

We can provide uniquely designed end seals with special seals, risers, flanges, or other variations, as well as custom imprinted or stamped molds.

Our molding capabilities go beyond filters to custom applications that may need urethane mold implementation.

Construction Capabilities

Sidco has a variety of construction materials and capabilities. These include reinforced support for high-pressure or high-flow applications, custom sizes, unique designs, and many others.

We work with each customer to create a design that fits their parameters.

End Caps, Potting, & Gaskets

Various specialty potting materials, molding compounds, and gasket materials are available for high-temperature or corrosive environments.

Styles & Configurations

Our most commonly manufactured filter styles are cylindrical, conical, panel, boxes, and V-banks. However, the combinations of filter styles and configurations we offer are almost infinite.

Specialty Materials

Media and materials include options rated for high temperatures, high performance, unique environments and range from 0.3 microns to 750 microns.

Customers may also provide proprietary materials for contract filter manufacturing projects.

Industries Served

Aircraft & Aerospace

Chemical

Construction

Electric Power

Environmental

Food & Beverage

General Industry

Health Care

Integrated Circuit Fabrication

Machining & Milling

Marine

Medical

Municipal Wastewater

Oil & Gas

Petrochemical

Power Generation

Pulp & Paper

Transportation

Request Custom Filter Quote

Fill out the form below and one of our team members will contact you within one business day.