All About Standard Radial Fin Filter Elements

Designed for Durability.

Radial fin filter elements, or Sewn End Filters, are used in applications with high temperature and chemical compatibility issues. We start with a standard design with an assortment of available options.

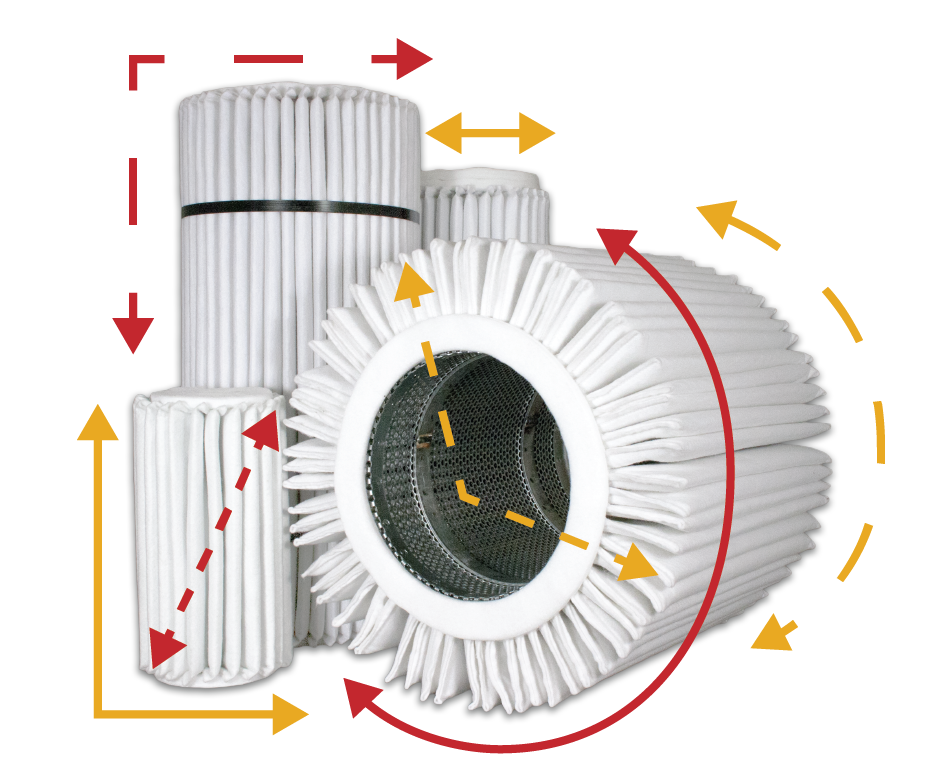

Standard Construction

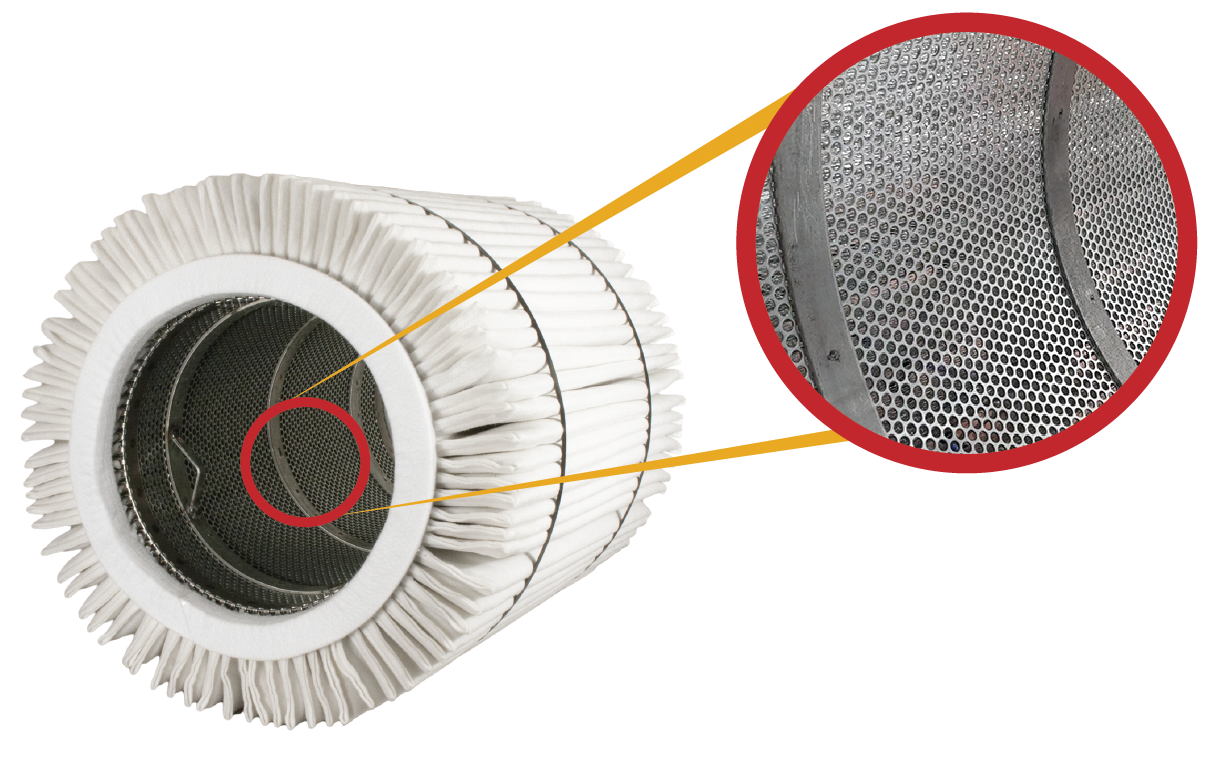

- Perforated carbon steel inner core

- 5µ or 10µ polyester felt media

- Polyester felt gaskets on both ends

Backwashing Screens

- Reverse fluid flows require a backwashing screen

- Secures textile media from displacement during back pulsing

Support Rings & Lift Lugs

- Provides robust reinforcement to the inner core

- Safeguards against collapse caused by pressure

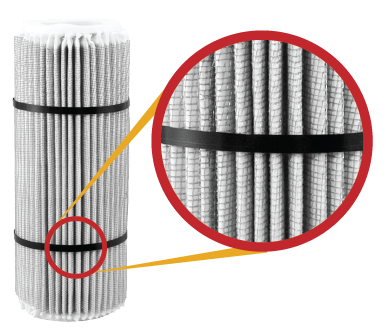

Outer Support Bands

- Provides structural stability and reinforcement to filter media

- Outer support bands can be added to any filter

Contact us to start your Sewn End Filter project today!

Our design and engineering team is happy to work with you on design, pricing, and application for your custom Sewn End Filter or Radial Fin Filter needs.

Read More Posts Like This One:

Watch Now: Custom Filter Manufacturing: Custom Radial Fin Filter Elements

We use advanced manufacturing techniques to design and build radial fin filter elements that meet your specifications. Radial fin filter elements are used in applications with high temperature and chemical compatibility issues because these filters can be made with no adhesive or chemical compounds… Watch Now!

Sidco Sales Tip: Close 27% More Sales

Derek Darling, President of Sidco Filter Company, talks about the easy tactic he uses to close 27% more sales…Watch Now!

Manufacturing to Serve OEMs

Our team can help you design, prototype, and manufacture HEPA, ULPA, and ASHRAE filters for your air cleaning applications…Read More